Ipleyiti yensimbi engenasici

Ingcaciso yeMveliso

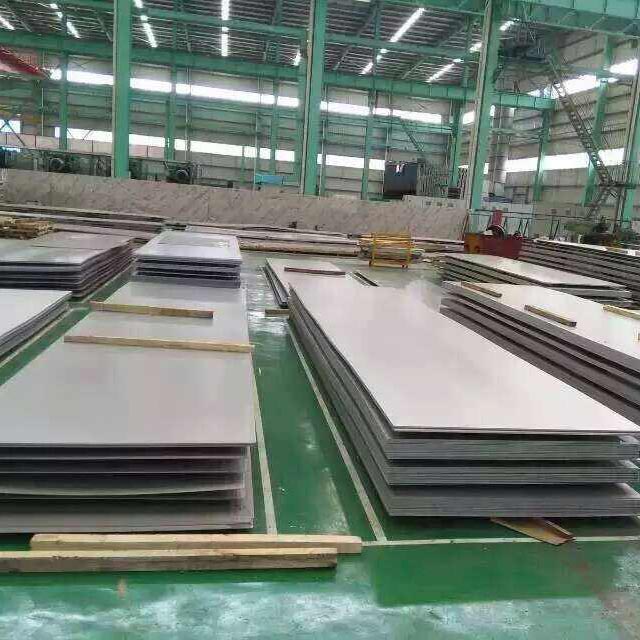

Ngokwendlela yokuvelisa, kukho iindidi ezimbini zokuqengqeleka okushushu kunye nokuqengqeleka okubandayo, kubandakanya i-0.5-4 mm yeshiti elishinyeneyo kunye ne-4.5-35 mm ipleyiti.

Ngokweempawu zesakhiwo sentsimbi, inokwahlulwa ibe ziindidi ezintlanu: i-austenite, i-austenitic-ferrite, i-ferrite, i-martensite kunye nokuqina kwemvula.

Indawo yokusetyenziswa: thwala ukubola kwe-oxalic acid, i-sulfate-ferric sulfate, i-nitric acid, i-nitric acid-hydrofluoric acid, i-sulfate-copper sulfate, i-phosphoric acid, i-formic acid, i-acetic acid kunye nezinye ii-acids.

Usetyenziso: olusetyenziswa kwiikhemikhali, ukutya, amayeza, iphepha, i-oyile, amandla e-athomu kunye namanye amashishini, kunye namacandelo ahlukeneyo kunye namacandelo ezakhiwo, ikhitshi, i-tableware, izithuthi kunye nezixhobo zendlu.Ukuze kuqinisekiswe ukuba amandla isivuno, amandla tensile, elongation, ubulukhuni kunye nezinye iimpawu mechanical ezahlukeneyo iipleyiti steel stainless ukuhlangabezana neemfuno, iipleyiti zentsimbi kufuneka annealing, unyango isisombululo, unyango ukwaluphala kunye nolunye unyango ubushushu phambi kokunikezelwa.

Iimfuno zomgangatho: ipleyiti yensimbi engenasici inomgangatho ogudileyo, iplastikhi ephezulu, ukuqina kunye namandla omatshini, kwaye iyamelana nokubola kweasidi, igesi yealkali, isisombululo kunye nolunye uhlobo lweendaba.Yintsimbi ekungelula ukuyirusa, kodwa ayinayo umhlwa kwaphela.Ukuxhatshazwa kwe-corrosion yensimbi engenasici ngokuyinhloko kuxhomekeke ekubunjweni kwe-alloy yayo (i-chromium, i-nickel, i-titanium, i-silicon, i-aluminium, njl.) kunye nesakhiwo sangaphakathi.Indima ephambili yichromium.I-Chromium inozinzo oluphezulu lweekhemikhali, inokwenza ifilimu ye-passivation kwindawo yentsimbi, ihlukanise isinyithi ngaphandle, ikhusele ipleyiti yensimbi kwi-oxidation, kwaye yandise ukunyanzeliswa kwe-corrosion ye-steel plate.Emva kokuba ifilimu ye-passivation ibonakaliswe, ukuxhathisa kwe-corrosion kuya kuncipha.

Ukuqulunqwa kwemichiza

| Ikhowudi yokufundisa emanyeneyo | Uphawu | Ukwakheka kwemichiza (iqhezu lobunzima)/% | ||||||||||||||||||||||||||||||||||

| c | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | Okunye | ||||||||||||||||||||||||||

| S30408 | 06Cr19Ni10 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00~ 10.50 | 18.00 ~ 20.00 | 0.10 | |||||||||||||||||||||||||||

| S30403 | 022Cr19Nil0 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00~ 12.00 | 18.00 ~ 20.00 | 一 | 一 | 一 | |||||||||||||||||||||||||

| S30409 | 07Cr19Ni10 | 0.04~0.10 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00~ 10.50 | 18.00 ~ 20.00 | 一 | |||||||||||||||||||||||||||

| $31008 | 06Cr25Ni20 | 0.04~ 0.08 | 1.50 | 2.00 | 0.035 | 0.020 | 19.00 ~ 22.00 | 24.00 ~ 26.00 | ||||||||||||||||||||||||||||

| S31608 | 06Cr17Ni12Mo2 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00~ 3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31603 | 022Cr17Ni12Mo2 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00-3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31668 | 06Cr17Ni12Mo2Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00~ 3.00 | 一 | 一 | Ti≥5C | ||||||||||||||||||||||||

| S39042 | 015Cr21M26Mo5Cu2 | 0.020 | 1.00 | 2.00 | 0.030 | 0.010 | 24,00~ 26.00 | 19.00 ~ 21.00 | 4.00~5.00 | 0.10 | 1.20~2.00 | 一 | ||||||||||||||||||||||||

| S31708 | 06Cr19Ni13Mo3 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00 ~ 20.00 | 3.00~4.00 | 0.10 | 一 | 一 | ||||||||||||||||||||||||

| S31703 | 022Cr19Ni13Mo3 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00 ~ 20.00 | 3.00~ 4.00 | 一 | ||||||||||||||||||||||||||

| S32168 | 06Cr18Nil1Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 9.00 ~ 12.00 | 17.0 ~ 19.00 | Ti≥5C | |||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Ikhowudi yenombolo edibeneyo | Uphawu | Ukwakheka kwemichiza (iqhezu lobunzima)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | Okunye | ||||||||||||||||||||||||||

| 68 | S21953 | 022Cr19Ni5Mo3S2N | 0.030 | 1.30 ~ 2.00 | 1.00~ 2.00 | 0.030 | 0.020 | 18.00 ~ 19.50 | 4.50~ 5.50 | 2.50~ 3.00 | 一 | 0.05~ 0.12 | 一 | |||||||||||||||||||||||

| 70 | S22253 | 022Cr22Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 21.00 ~ 23.00 | 4.50~ 6.50 | 2.50~ 3.50 | 0.08~ 0.20 | 一 | ||||||||||||||||||||||||

| 71 | S22053 | 022Cr23Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 22.00 ~ 23.00 | 4.50~ 6.50 | 3.00~ 3.50 | 一 | 0.14~ 0.20 | 一 | |||||||||||||||||||||||

| Ukubunjwa kweekhemikhali zezinye iimpawu kwitheyibhile zihluke kwi-GB / T 20878 | ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Ikhowudi yokufundisa emanyeneyo | Uphawu | Ukwakheka kwemichiza (iqhezu lobunzima)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Okunye | |||||||||||||||||||||||||||

| 78 | S11348 | 96C-13A | 0.08 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50~ 14.50 | 0.60 | - | - | Al:0.10~0.30 | ||||||||||||||||||||||||

| 92 | S11972 | 019Cr19Mo2NbTi | 0.025 | 1.00 | 1.00 | 0.035 | 0.020 | 17.50 ~ 19.50 | 1.00 | 1.75~2.50 | 0.035 | (Ti+Nb) [0.20+4 (C+N)] ~0.80 | ||||||||||||||||||||||||

| 97 | S11306 | 06Cr13 | 0.06 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50~13.50 | 0.60 | 一 | 一 | |||||||||||||||||||||||||

| Ukubunjwa kweekhemikhali zezinye iimpawu kwitheyibhile zihluke kwi-GB / T 20878 | ||||||||||||||||||||||||||||||||||||

Ukutyeba okusemgangathweni

Ububanzi bepleyiti yentsimbi:

1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm.

Non-iplate ubude: 1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm inokumiselwa ngokweemfuno zabathengi.

Icandelo lokuqengqeleka elibandayo:

ipleyiti steel stainless ebandayo rolled 2B (coil, strip, flat plate) ipleyiti uphawu: 3 5mm—6mm 304/2B, 316L/2B.

Ukutyeba: kubanda kuqengqeleka 2B (0.1-6.0mm).

Umphezulu: 2B umphezulu ogudileyo, BA.

8K isipili;Umzobo wocingo kunye nesanti;Isanti yekhephu;Ipleyiti yentsimbi engenazinwe.

Iphaneli yokuhlobisa: ipleyiti yombala, i-titanium plate, i-etching plate, i-oil polishing hairline plate (HL, NO.4), i-3D ipleyiti ye-3D, i-sandblasting plate, i-plate embossed.

Hot rolling isebe: steel stainless ipleyiti hot rolling No.1 (coil, flat plate).

Ukutyeba: ishishini No.1 (3-159mm).

Umphezulu: 8K umphezulu wesipili;Umzobo wocingo, i-titanium plating, isanti;Isanti yekhephu;Ipleyiti yentsimbi engenazinwe.