Ipleyiti yentsimbi ekhandiweyo

Ukuhlelwa kunye nokuSetyenziswa

Ngokweendlela zokuvelisa kunye nokucubungula, inokwahlulwa ngokwezi ndidi zilandelayo:

1.Ipleyiti yentsimbi edityanisiweyo. Olu hlobo lwepleyiti yentsimbi lwenziwe ngendlela yokudipha eshushu, kodwa ifudunyezwa kwi-alloy coating ye-zinc kunye nentsimbi yenziwe malunga ne-50O ℃. Eli phepha lifakwe igalvanized line-adhesion elungileyo yokunamathela ngesondo kunye nokuwelda.

2.Ipleyiti yentsimbi enezitshizi eshushu-diphu. Gxininisa ipleyiti yentsimbi kumgama otyhidiweyo weDuo ukuze ibambelele kumaleko wepleyiti yentsimbi yeDuo.

Okwangoku, iveliswa ikakhulu yinkqubo eqhubekayo yokugalela, oko kukuthi, ipleyiti yentsimbi eqengqelekayo iqhubeka intywiliselwa kwindawo yokuhlambela ye-zinc etyhidiweyo ukwenza ipleyiti yentsimbi.

3.Electrogalvanized steel plate. Ishiti lentsimbi ekhandiweyo elenziwe ngendlela ye-electroplating inokusebenza kakuhle. Nangona kunjalo, i-coating incinci kwaye ukuxhathisa umhlwa akulunganga njengaleyo yeshiti elishushu-diphu; ④ I-alloy kunye ne-composite steel galvanized plate. Yintsimbi yentsimbi eyenziwe ngezinc kunye nezinye iintsimbi ezifana nelothe kunye nezinc. Olu hlobo lwepleyiti yentsimbi alunamsebenzi obalaseleyo wokuchasana nomhlwa kuphela, kodwa lunokusebenza kakuhle kokugquma.

4.Ipleyiti yentsimbi enecala elinye enecala elinye kunye necala eliphindwe kabini lokwahluka kwepleyiti yentsimbi enecala elinye icala elinye, oko kukuthi, iimveliso ezifakwe kwicala elinye kuphela. It has ukulungelelaniswa ngcono ngaphezu kabini-macala iphepha lagalvanized kwi welding amalahle, ukutyabeka, unyango anti-umhlwa, processing, njalo njalo Ukuze ukoyisa elingeloncedo yokungagqumeki zinc kwelinye icala, kukho olunye uhlobo sheet amazi ziqatywe umaleko obhityileyo zinc kwelinye icala, oko kukuthi, kabini kunye umahluko sheet zinc.

5.I-alloy kunye nepleyiti yentsimbi ehlanganisiweyo. Yintsimbi yentsimbi eyenziwe nge-zinc kunye nezinye iintsimbi ezifana ne-aluminium, i-lead, i-zinc, njl.

Ukongeza kwezi ntlobo zintlanu zingasentla, kukwakho ipleyiti yentsimbi enombala, ushicilelo olufakwe ipleyiti yentsimbi, ipleyiti yentsimbi yePVC elaminethiweyo, njl.

Imbonakalo

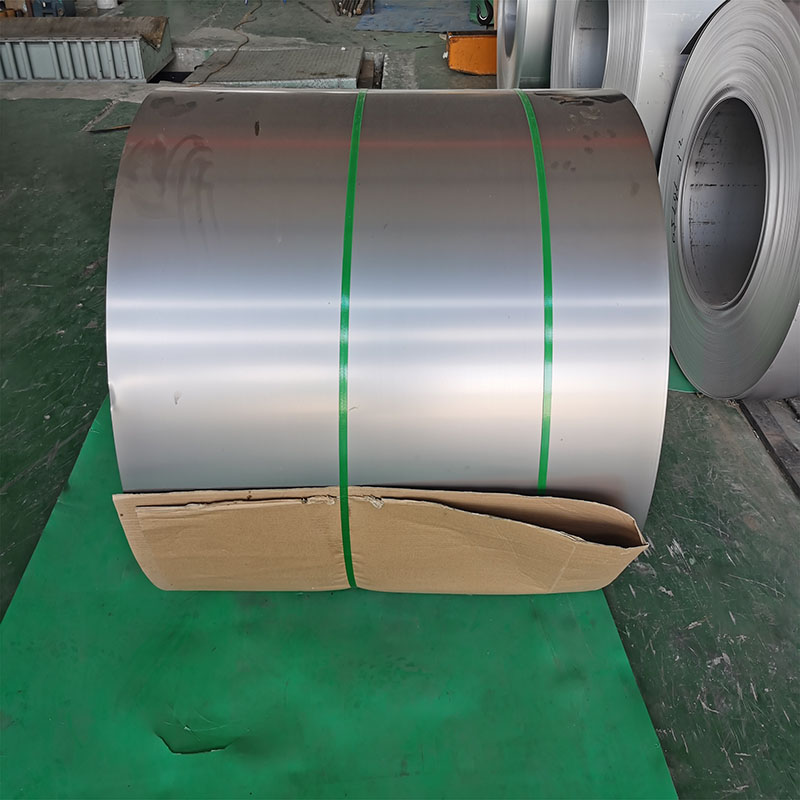

1. Ukupakishwa

Inokwahlulwa ibe ziindidi ezimbini: ishidi legalvanized lisikwe kubude obusisigxina kunye nephepha legalvanized coil. Ukupakishwa kwe-iron ngokubanzi kufakwe iphepha elikhusela ukufuma, kwaye umphandle ubotshwe ngentsimbi esinqeni, ebotshelelwe ngokuqinileyo ukukhusela i-galvanized sheet yangaphakathi ukuba ingakhuhlani omnye komnye.

2. Inkcazo kunye nobukhulu

Imilinganiselo yemveliso efanelekileyo (enjengale ilandelayo kunye) dwelisa imilinganiselo ecetyiswayo, ubukhulu, ubude nobubanzi beshiti legalvanized kunye neziphene zalo ezivumelekileyo. Ukongezelela, ububanzi kunye nobude bebhodi kunye nobubanzi bomqulu bunokumiselwa ngokwesicelo somsebenzisi.

3. Umphezulu

Imeko ngokubanzi: ngenxa yeendlela ezahlukeneyo zonyango kwinkqubo yokugquma, imeko ngokubanzi yephepha elifakwe i-galvanized nayo yahlukile, njengemeko eqhelekileyo ye-zinc flake, i-flake ye-zinc ecocekileyo, i-flake ye-zinc flat, i-zinc-free flake kunye nonyango lwe-phosphating. I-galvanized sheet kunye ne-galvanized coil enqunyulwe ubude obusisigxina ayiyi kuba naziphi na iziphene ezichaphazela ukusetyenziswa (njengoko kuchazwe ngezantsi), kodwa i-coil iya kuvunyelwa ukuba ibe neengxenye ze-welding kunye nezinye iindawo ezingenasiphako.

4. Ubungakanani begalvanizing

Ixabiso lesikali sobungakanani begalvanizing: ubungakanani begalvanizing yindlela eyamkelwe ngokubanzi kwaye iluncedo ukubonisa ubukhulu be-zinc yokwambathisa kwiphepha elenziwe ngegalvanized. Kukho iindidi ezimbini zokufakwa kwe-zinc: ubungakanani obufanayo be-zinc plating kumacala omabini (oko kukuthi ubukhulu obulinganayo be-zinc plating) kunye nobungakanani obahlukileyo be-zinc plating kumacala omabini (okt. Iyunithi yobungakanani begalvanizing yi-g/m.

5. Umsebenzi womatshini

(1) Uvavanyo lwe-tensile: xa sithetha ngokubanzi, ukuba nje iphepha elifakwe igalvanized loyilo, umzobo kunye nomzobo onzulu uneemfuno zomsebenzi oqinileyo.

(2) Umfuniselo wokugoba: Ligama elibalulekileyo ukuvayisha umsebenzi wetekhnoloji wepleyiti ebhityileyo. Nangona kunjalo, iimfuno zamazwe ahlukeneyo kwiindidi ezahlukeneyo zamaphepha afakwe igalvanized zahlukile. Ngokuqhelekileyo, emva kokuba i-galvanized sheet igobe i-180 °, i-zinc layer ayiyi kushiya iphrofayili yangaphandle, kwaye isiseko sephepha asiyi kuchithwa okanye siphulwe.

Iimpawu zentsimbi yentsimbi: i-galvanizing inokuthintela ngokufanelekileyo ukubola kwensimbi kunye nokwandisa ubomi benkonzo. Ishiti lentsimbi ekhuselweyo (ubukhulu obuyi-0.4 ~ 1.2mm) ikwabizwa ngokuba yi-galvanized iron sheet, eyaziwa ngokuba yi-white iron sheet. Ishiti lensimbi eliphekiweyo lisetyenziswa ngokubanzi kulwakhiwo, izithuthi, izixhobo zendlu, iimfuno zemihla ngemihla kunye namanye amashishini.

Ubungakanani: ngokweemfuno zabathengi, ubude kunye nobubanzi bunokulungiswa okanye ngokwezifiso.

Ubume bomphezulu: Ngenxa yeendlela ezahlukeneyo zonyango kwinkqubo yokugquma, umgangatho wephepha le-galvanized ukwahluka, njenge-flake ye-zinc eqhelekileyo, i-zinc flake, i-flake ye-zinc flat, i-flake engeyiyo i-zinc kunye ne-phosphating surface. Umgangatho waseJamani ukwachaza umgangatho ongaphezulu.

Iphepha legalvanized liya kuba nenkangeleko elungileyo kwaye aliyi kuba neziphene ezinobungozi ekusebenziseni imveliso, njengokuba akukho plating, imingxuma, iintanda, i-scum, ngaphezulu kwe-plating ubukhulu, imikrwelo, ubumdaka be-chromic acid, umhlwa omhlophe, njl. Ezinye iziphene ezithile ziya kudweliswa kwikhontrakthi xa kuodolwa.

Iipropati zoomatshini

Uvavanyo lwe-tensile:

1.Isalathiso sokwenziwa komsebenzi: Ngokuqhelekileyo, liphepha elenziwe igalvanized kuphela lesakhiwo, umzobo kunye nomzobo onzulu oneemfuno zepropathi ezithambileyo. Icwecwe elifakwe igalvanized lesakhiwo liya kuba nenqaku lesivuno, ukomelela kunye nobude; Ubude kuphela obufunekayo ukolula. Jonga imigangatho yemveliso efanelekileyo kwi "8" yeli candelo malunga namaxabiso athile.

2.Indlela yokuvavanya: iyafana nendlela yokuvavanya ishidi lentsimbi eqhelekileyo, jonga imigangatho efanelekileyo ebonelelwe "kwi-8" kunye nemigangatho yendlela yokuvavanya edweliswe kwi-"Odinary carbon steel sheet".

Ukugoba uvavanyo:

Uvavanyo lokugoba yeyona nto iphambili yokulinganisa ukusebenza kwethekhinoloji yephepha, kodwa iimfuno zemigangatho eyahlukeneyo yesizwe kumaphepha ahlukeneyo anezinki azihambelani. Imigangatho yaseMelika ayifuni ukugoba kunye novavanyo lwe-tensile ngaphandle kwebakala lolwakhiwo. EJapan, iimvavanyo zokugoba ziyafuneka ngaphandle kolwakhiwo, lwezakhiwo kunye neepleyiti zamathanki ngokubanzi.

Iimfuno: ngokuqhelekileyo, emva kokuba i-galvanized sheet igobe i-180 °, akuyi kubakho ukuhlukana kwe-zinc layer kumphezulu wangaphandle, kwaye akuyi kubakho ukuqhekeka kunye nokuqhekeka kwisiseko seplate.

Iimpawu kunye nokusebenza

Umbala ipleyiti ipleyiti ukutyabeka imveliso eyenziwe ipleyiti epholileyo eqengqiwe, ipleyiti intsimbi, ityatyekwe (umqulu coated) okanye composite bhanyabhanya eziphilayo (PVC film, njl.) emva unyango imichiza phezu komhlaba, kwaye emva koko yabhakwa kwaye wanyangwa. Abanye abantu baphinda babize le mveliso "i-roller coated steel plate", "iplate yentsimbi yombala weplastiki". Iimveliso zepleyiti yombala ziqengqeleka ngabavelisi kwimigca yokuvelisa eqhubekayo, ngoko ke zikwabizwa ngokuba yimiqulu yeplate yentsimbi efakwe umbala. Ipleyiti yensimbi yombala ayinayo kuphela amandla omatshini aphezulu entsimbi kunye nezixhobo zetsimbi, kulula ukwenza umsebenzi, kodwa kunye nezinto ezintle zokuhombisa kunye nokuxhathisa ukubola. Ipleyiti yentsimbi yombala yinto entsha kwihlabathi lanamhlanje. Ngenkqubela phambili yesayensi kunye nobuchwepheshe, ukuphuculwa kolwazi lokusingqongileyo, ukuphuculwa kwemigangatho yokuphila kwabantu, ipleyiti yombala yentsimbi yezindlu eziphathwayo ngakumbi nangakumbi ibonisa amandla anamandla kunye namathemba emarike abanzi, ngokwakhiwa, izixhobo zekhaya, oomatshini kunye nombane, ukuthutha, ukuhombisa kwangaphakathi, izixhobo zeofisi kunye namanye amashishini athandwayo.

Umgangatho weMveliso

I-JIS G3302-94 ishidi lentsimbi;

I-JIS G3312-94 ipeyintiwe iphepha lentsimbi;

I-JIS G3313-90 (96) Ishidi lensimbi ye-electrogalvanized kunye nomtya; Iimfuno ngokubanzi zeshiti lentsimbi enentsimbi eshushu-diphu;

I-ASTM i-A526-90 ibakala lorhwebo ishidi lentsimbi eshushu-diphu;

I-ASTMA 527-90 (75) ivalwe ishidi lentsimbi edibeneyo eshushu;

I-ASTMA528-90 ishidi lentsimbi efakwe nzulu eshushu-diphu; Idiphu eshushu icwecwe lentsimbi yophahla kunye nepaneli yodonga;

I-ASTMA44-89 icwecwe lentsimbi eshushu yokudipha kwimisele;

I-ASTM i-A446-93 imigangatho yesakhiwo sentsimbi eshushu-diphu;

I-ASTMA59-92 icwecwe elibandayo eliqengqelekayo lentsimbi;

I-ASTMA642-90 icwecwe lentsimbi elidiphu elishushu elidiphulwe nzulu;

Γ OCT7118-78 iphepha lentsimbi;

I-DINEN10142-91 Icandelo le-1 Intsimbi ephantsi ye-carbon steel eshushu-dip intsimbi yentsimbi kunye nepleyiti yensimbi;

I-DIN1012-92 inxalenye ye-2 ishidi lentsimbi eshushu-diphu.

Umgangatho woVavanyo

I-JIS H0401-83 Indlela yokuvavanya ye-galvanizing yediphu eshushu;

I-DIN50952-69 Indlela yokuvavanya ye-galvanizing yediphu eshushu.

Ekujoliswe kuko

Iimveliso zeshiti kunye neemveliso zentsimbi zisetyenziswa ikakhulu kulwakhiwo, kushishino olulula, iimoto, ezolimo, ukufuya izilwanyana, ukuloba, urhwebo kunye namanye amashishini. Ushishino lolwakhiwo lusetyenziswa ikakhulu ukwenza iipaneli zophahla oluchasene nomhlwa kwimizi-mveliso kunye nezakhiwo zoluntu, iigridi zephahla, njl. Umzi-mveliso wokukhanya uyisebenzisela ukwenza amaqokobhe esixhobo sesixhobo sasekhaya, iitshimini zasekuhlaleni, izixhobo zasekhitshini, njl. Ezolimo, ukufuywa kwezilwanyana kunye nokuloba zisetyenziswa ikakhulu njengokugcinwa kokutya kunye nokuthutha, izixhobo zokulungisa umkhenkce wenyama kunye neemveliso zasemanzini, njl. Urhwebo lusetyenziswa ikakhulu njengokugcinwa kunye nokuhanjiswa kwezinto, izixhobo zokupakisha, njl.